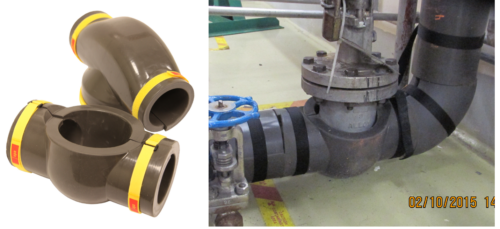

Pipe and Valve Shielding

T-Flex® is the most versatile shielding material that NPO has to offer. Its ability to be poured as a liquid and cured as a flexible solid makes it ideal for fitting the maximum amount of shielding around a component while keeping space and weight to a minimum. The most common way this is put into practice it through pipe and valve shielding. NPO is able to conform the shielding snugly around a pipe and valve which brings the most shielding possible closest to the source while staying clear of any interferences in the immediate area. Below is a showcase of different pipe and valve shields NPO has made over the last few years.

More Information

Large Scale Pipe and Valve Shielding

The versatility of T-Flex® extends passed isolated valves, elbows, and short runs of piping. Some projects require extensive shielding across multiple pipe sizes and various valves and bends. The NPO engineering team uses a combination of plant drawings, laser scan data, picture references, and computer aided design software to create a completely custom, form fitting shielding package.

In plants like Perry and Davis-Besse, these huge installations have become permanent shielding and eliminated the need for blocking off high dose areas.

Read more about Davis-Besse in the link below.

Permanent Shielding at Davis-Besse

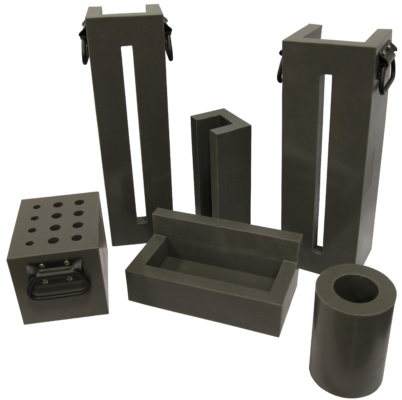

Mold Making Capabilities

The flexible nature of T-Flex® not only applies to the material itself, but it’s ability to take any shape needed for a given application. With use of computer aided design software, NPO can create virtually any shaped shield as a plant needs in order to fit around, cover, hold, or be inserted near whatever requires shielding.

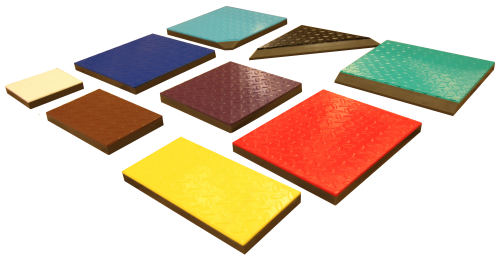

Variety of Colors and Shapes

NPO can add a color layer to any tile. Different colors can help differentiate pieces in an assembly, act as a warning, or just make the shielding visually appealing.