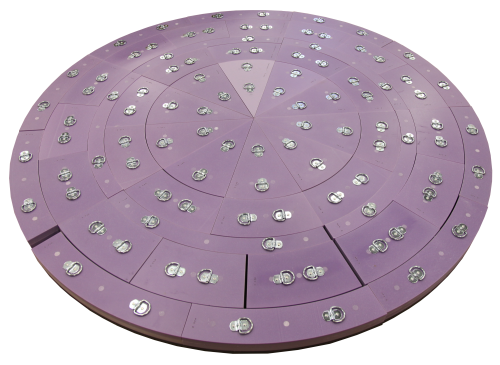

Canister lid shields provide significant gamma and neutron protection from shine emitted from the canister lid. These shields are sized for whatever canister they are to be used on. The modular design allow for the removal of pieces only in the required areas to maximize dose reduction.

T-Flex® and Borated Polyethylene Composite Shielding

This shielding consists of 2” of borated polyethylene plastic, and excellent neutron radiation attenuator, integrated on top of 1” of T-Flex® Tungsten. This shielding system provides about 75% dose deduction from neutron radiation as well as a significant amount of dose reduction from gamma sources. Pieces are modular, weigh less than 40 lb each, and are split per the specifications from the canister manufacturer.

Designed for Specific Applications

The conditions surrounding the canister and operations taking place varies from plant to plant, and not every situation can be easily shielded with a multi-piece full lid shielding package. Temperature, weld operations, space restrictions, and attenuation goals all play a factor in the design of canister lid shielding.

Canister Ring at Davis-Besse

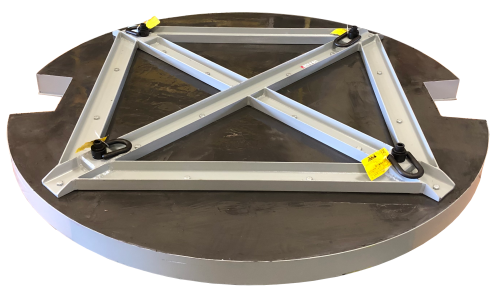

Single-Lift Shield

If the resources are available, the canister lid shield can be a single piece that is lifted into place. The sturdy steel frame is filled with a combination of T-Flex gamma and neutron shielding. The notches on the side allow access to vents and ports, and separate pieces can be placed there when needed. A plastic pad on the bottom side ensures zero steel-to-steel contact, keeping the canister lid from being scratched.