Blog

T-Flex Pipe and Valve Shields

February 3, 2017

T-Flex is the most versatile shielding material that NPO has to offer. Its ability to be poured as a liquid and cured as a flexible solid makes it ideal for fitting the maximum amount of shielding around a component while keeping space and weight to a minimum. The most common way this is put into practice is through pipe and valve shielding. NPO is able to conform the shielding snugly around a pipe and valve which brings the most shielding possible closest to the source while staying clear of any interferences in the immediate area. Below is a showcase of different pipe and valve shields NPO has made over the last few years.

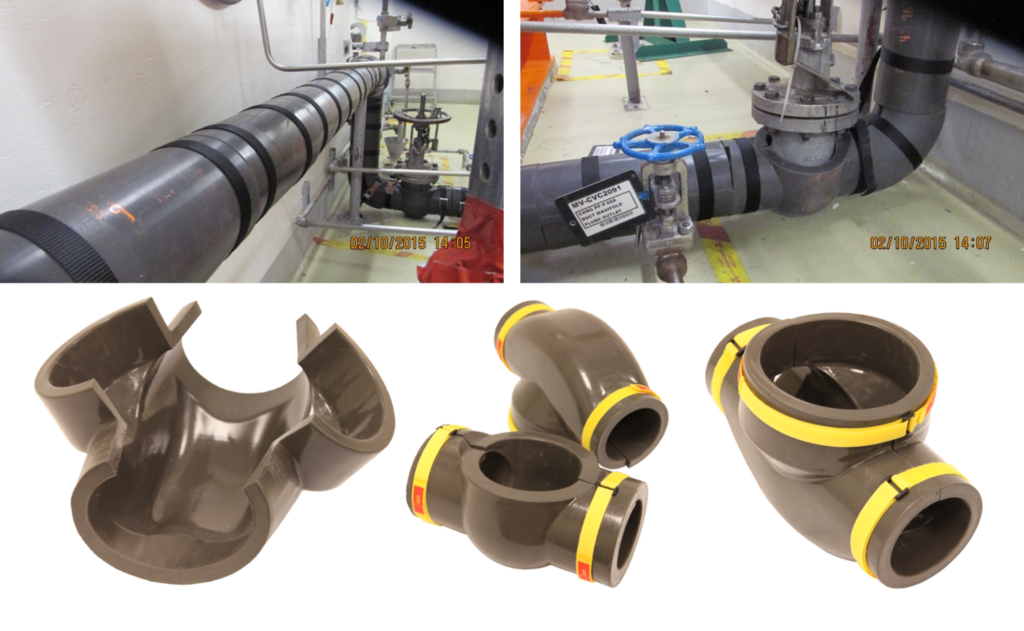

Custom Valves, Elbows, Straight Pipe Sections

NPO was able to create custom fit valve shields based on pictures and reference dimensions. The first group of pictures are from a plant that was wanted to remove the locker high rad status from the area. They were able to do so using T-Flex Tungsten shielding around two valves and straight sections of pipe.

This second group of pictures shows off pipe and valve shields for a vertical application. This shielding is intended to be permanent and features lockable steel banding to secure it all to the pipe. In addition, NPO made and elbow shield as well as a base for weight to be supported on and keep shielding from sliding through the gap in the grating. The base is also made of T-Flex Tungsten.

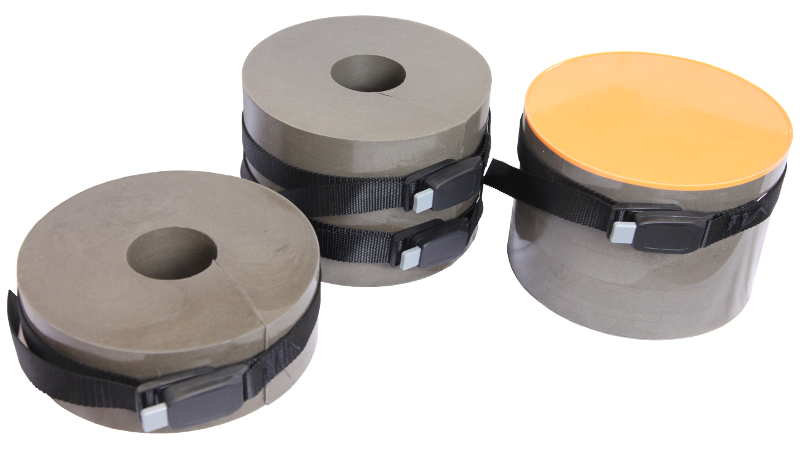

Pipe and End Caps for Pipe Removal

This T-Flex Bismuth shielding is 3″ thick and provides and estimated 82% dose reduction at Co-60 energy. This shielding was secured around a high dose pipe that was cut out and removed. The end cap pieces shield the cut out section on all sides, keeping the pipe shielded as it is moved for disposal.