T-Flex

T-Flex Shielding Overview

T-Flex shielding suspends high Z materials such as tungsten and bismuth in a polymer matrix to create radiation shielding that is non-toxic, flexible, and infinitely customizable. T-Flex was created to address some of the limitations and challenges of traditional lead shielding. The mixture of high Z material powder and polymer matrix provides both gamma and neutron attenuation. Since T-Flex is a liquid poured at room temperature, and subsequently solidified by curing, it can be made to virtually any shape and allows embedding of magnets, handles, or other specialty hardware. Its flexibility, non-toxic (no lead) composition, and surface finish allow it to be easily trimmed for field fitting and cleaned for decontamination. T-Flex can withstand higher temperatures than lead wool blankets. It is the best option for most industrial shielding applications.

NPO invented T-Flex over 20 years ago and manufactures it in our facility in Lisle, IL. It has since been deployed by dozens of Nuclear Power Plants, DOE facilities, and Naval Shipyards around the world.

T-Flex Blankets

NPO’s T-Flex® blankets are highly flexible non-lead shielding blankets with grommets located at the corners. These blankets come in the standard sizes shown in Ordering Info. They are ASTM E-84 Class A rated.

T-Flex® blankets are more flexible and versatile than their lead counter parts, making them perfect for wrapping around a pipe or hanging from racks or scaffolding. In the Ordering Info are the sizes of standard T-Flex® blankets. Other sizes are available upon request, both in the standard lead wool blanket sizes and custom as well.

Ribbons

T-Flex® Ribbons are highly flexible strips. These ribbons can be spiral wrapped around components for a quick “hot spot” solution. When a component with complex geometry, such has a valve, has difficult to acquire dimensions, T-Flex® Ribbons are an easy to implement shielding solution.

Standard ribbons include a silicone yellow layer for visibility, but ribbons can be made without this layer to maximize shielding effectiveness when coiled around pipe fittings and other components. The standard length is 8 feet and the material can be easily cut in the field using common cutting tools.

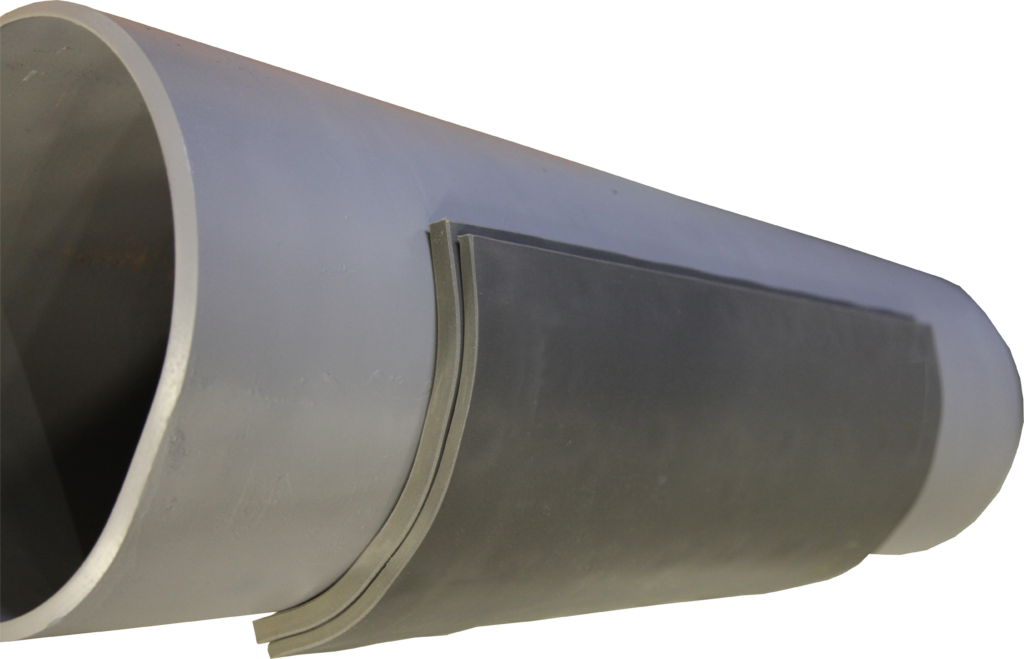

Pipe Shields

T-Flex® is the most versatile shielding material that NPO has to offer Its ability to be poured as a liquid and cured as a flexible solid makes it ideal for fitting the maximum amount of shielding around a component while keeping space and weight to a minimum.

The most common way this is put into practice is through pipe and valve shielding. NPO is able to conform the shielding snugly around a pipe and/or valve which bring the most shielding possible closest to the source while staying clear of any interferences in the immediate area.

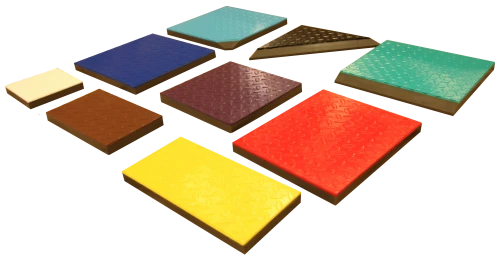

Floor Tiles

Designed to provide economical and ergonomic solutions for shielding sources below. Each tile combines the attenuation properties of T-Flex® with the durability of a work mat. They also can be cut and trimmed for in field adjustments. The floor shielding features a non-slip diamond tread surface.

T-Flex® floor tiles are perfect for bridges and platforms. In addition to the standard sizes available on the reverse side of this page, floor tiles can be made to custom fit any floor geometry while staying within weight limitations. NPO offers a variety of colors to help identify different pieces in a custom package.

Magnetic T-Flex

Magnetic T-Flex® radiation shielding (including magnetic tungsten and bismuth shielding) incorporates high strength magnets to adhere safely and securely to carbon steel surfaces. Magnetic radiation shielding offers significant reduction in installation time when compared to traditional shielding blankets or walls. It can be manufactured in custom shapes to suit unique applications. Various hanging hardware can be incorporated when a secondary restraint is required.

Custom

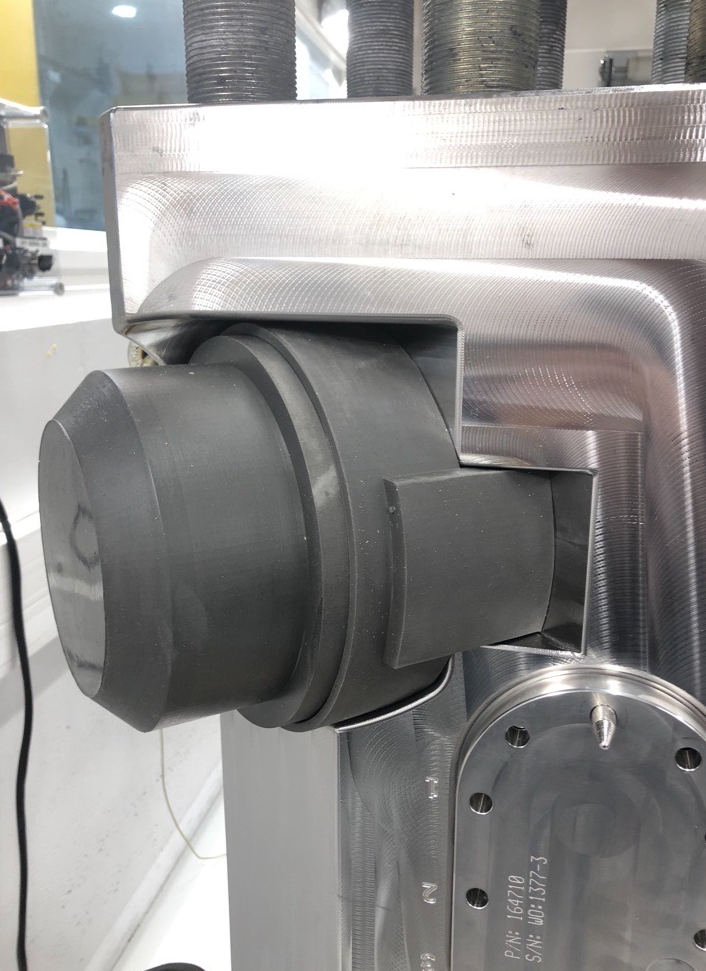

Pipe and Valve Shielding

T-Flex® is the most versatile shielding material that NPO has to offer. Its ability to be poured as a liquid and cured as a flexible solid makes it ideal for fitting the maximum amount of shielding around a component while keeping space and weight to a minimum. The most common way this is put into practice it through pipe and valve shielding. NPO is able to conform the shielding snugly around a pipe and valve which brings the most shielding possible closest to the source while staying clear of any interferences in the immediate area. Below is a showcase of different pipe and valve shields NPO has made over the last few years.

Large Scale Pipe and Valve Shielding

The versatility of T-Flex® extends passed isolated valves, elbows, and short runs of piping. Some projects require extensive shielding across multiple pipe sizes and various valves and bends. The NPO engineering team uses a combination of plant drawings, laser scan data, picture references, and computer aided design software to create a completely custom, form fitting shielding package.

In plants like Perry and Davis-Besse, these huge installations have become permanent shielding and eliminated the need for blocking off high dose areas.

Mold Making Capabilities

The flexible nature of T-Flex® not only applies to the material itself, but it’s ability to take any shape needed for a given application. With use of computer aided design software, NPO can create virtually any shaped shield as a plant needs in order to fit around, cover, hold, or be inserted near whatever requires shielding.

Variety of Colors and Shapes

NPO can add a color layer to any tile. Different colors can help differentiate pieces in an assembly, act as a warning, or just make the shielding visually appealing.

T-Flex Applications

- March 15, 2024

Browns Ferry 360-Inspection Platform

20230110_095324IMG_161420230120_100515

...

- February 20, 2024

Radiography Shielding

Radiography is a non-destructive testing (NDT) technique that uses a radioactive source to detect flaws or defects in the internal structures, typically pipes. This testing process requires an “exclusion...

- March 6, 2023

Custom Fit Meter Shielding

Some shielding applications require a precise fit in order to shield effectively. The meter of this instrument was a streaming source for the workers operating it. To fit the...

- January 9, 2023

Vogtle Reactor Head Shielding

In 2021, Vogtle reached out to NPO to help develop a new shielding package for around the reactor head. Their current system consisted of two rings: one under the...

- June 30, 2022

Oconee Reactor Head T-Flex Shielding

Reactor head shielding is an essential part of every refuel outage. Oconee Nuclear Station sought to upgrade the shielding used at the bottom of the reactor head, opting to...

- June 29, 2022

Brunswick Permanent Valve Shield Box

Brunswick Nuclear Station had a valve that was causing a room to be a locked high radiation area. They wished to implement a permanent shielding package in order to...